By Meredith Mendelsohn

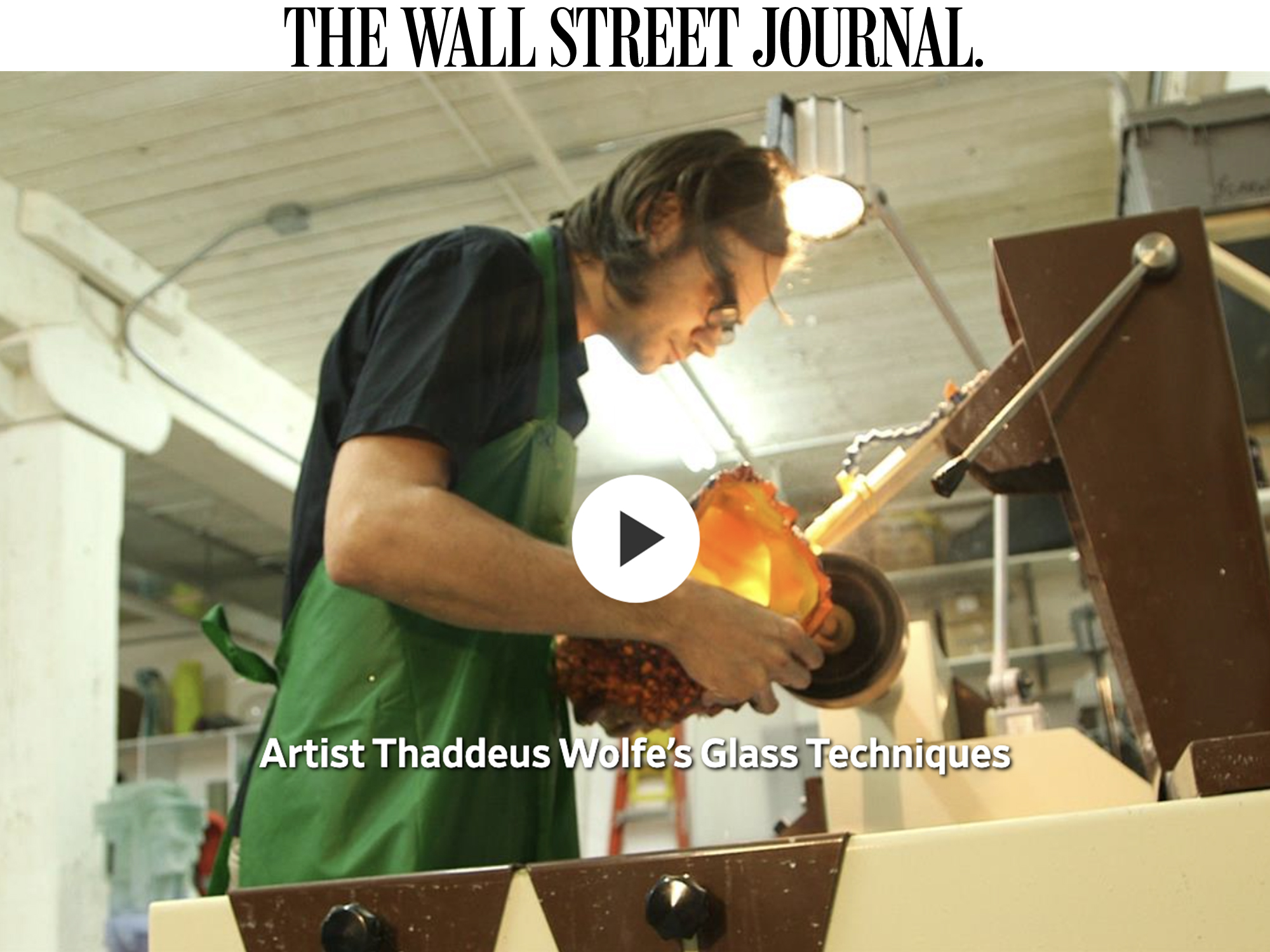

WHO: Artisan Thaddeus Wolfe, 36, makes one-of-a-kind vessels and lighting fixtures that straddle art and design, and combine the techniques of glassblowing and casting. Born in Toledo, Ohio, Mr. Wolfe set out to be a painter. But he has blown glass since 1999, when he was hooked by a course at the Cleveland Institute of Art, from which he received his MFA in 2002. “It’s very addictive—a challenge and a gamble,” said Mr. Wolfe of glassmaking. “A piece could break at the very end of the process, after over a week of work.”

WHAT: Mr. Wolfe made this 13.5-inch vessel, which he calls a faceted assemblage, for his first solo show, at New York design gallery R & Company this fall. “The idea of grinding through layers came of seeing interesting results in earlier works when I unintentionally sanded through the color,” he said.

HOW: First, the artist crafts a Styrofoam form, nearly the shape of the object he hopes ultimately to create. Using a hot-glue gun, he pieces together cut or torn hunks of the material, then scores textures and patterns into the material with a scalpel. He then slathers the form with a thick mixture of plaster and silica reinforced with chicken wire. When the mold has air-dried, he digs out every bit of Styrofoam with a dental tool, leaving it hollow.

Now, to the glass: Mr. Wolfe dips a steel blowpipe into clear molton glass then immerses that in different-hued glass he has melted in pots—not unlike cups of Easter-egg dye. After layering colors until he has an evenly thick-walled blob, he uses tools to pound and stretch it on a table to achieve the shape—in this case, oblong—the mold needs. (Mr. Wolfe frequently inserts the glass into a gas-fired metal cylinder to keep it from cooling.) For this vessel, he then rolled the piece in crushed gray and black glass.

Taking enormous breaths, the designer then blows the glob into the cavity of the mold, which has been heated to 1,100 degrees in a kiln for at least a day. The mold must remain hot so the liquid glass, itself 2,000 degrees, doesn’t solidify before it has slid into every crevice of the mold, said Mr. Wolfe.

The project cools for several days before Mr. Wolfe cracks off the mold. Taking up a diamond saw and an angle grinder, among other machines—and using lots of water to reduce friction—he cuts and polishes away the crusty surface of gray and black glass, revealing deeper layers. “You never know exactly how it’s going to turn out,” he said.

WHY: While visiting the natural- history wing of the Smithsonian Museum in 2008, Mr. Wolfe admired chunks of pyrite, a mineral known as “fool’s gold” for tricking prospectors centuries ago. “It looked like something a cubist artist could have made,” he said. “I wanted to re-create the experience of seeing something and not knowing whether it was natural or man-made.”

WHERE: Mr. Wolfe works out of a large space in the basement of an industrial building in Brooklyn. “It’s messy, what I do. I use a lot of water, especially when I’m polishing and grinding,” he said. “Luckily the studio had a drain in the floor, into which I can plumb all the wastewater.”