By Ruth Bloomfield

A vision of the future of design is unfolding in a small studio outside of Amsterdam: Robots building bookshelves. Computers designing furniture. A chair that can be downloaded and built with a 3-D printer.

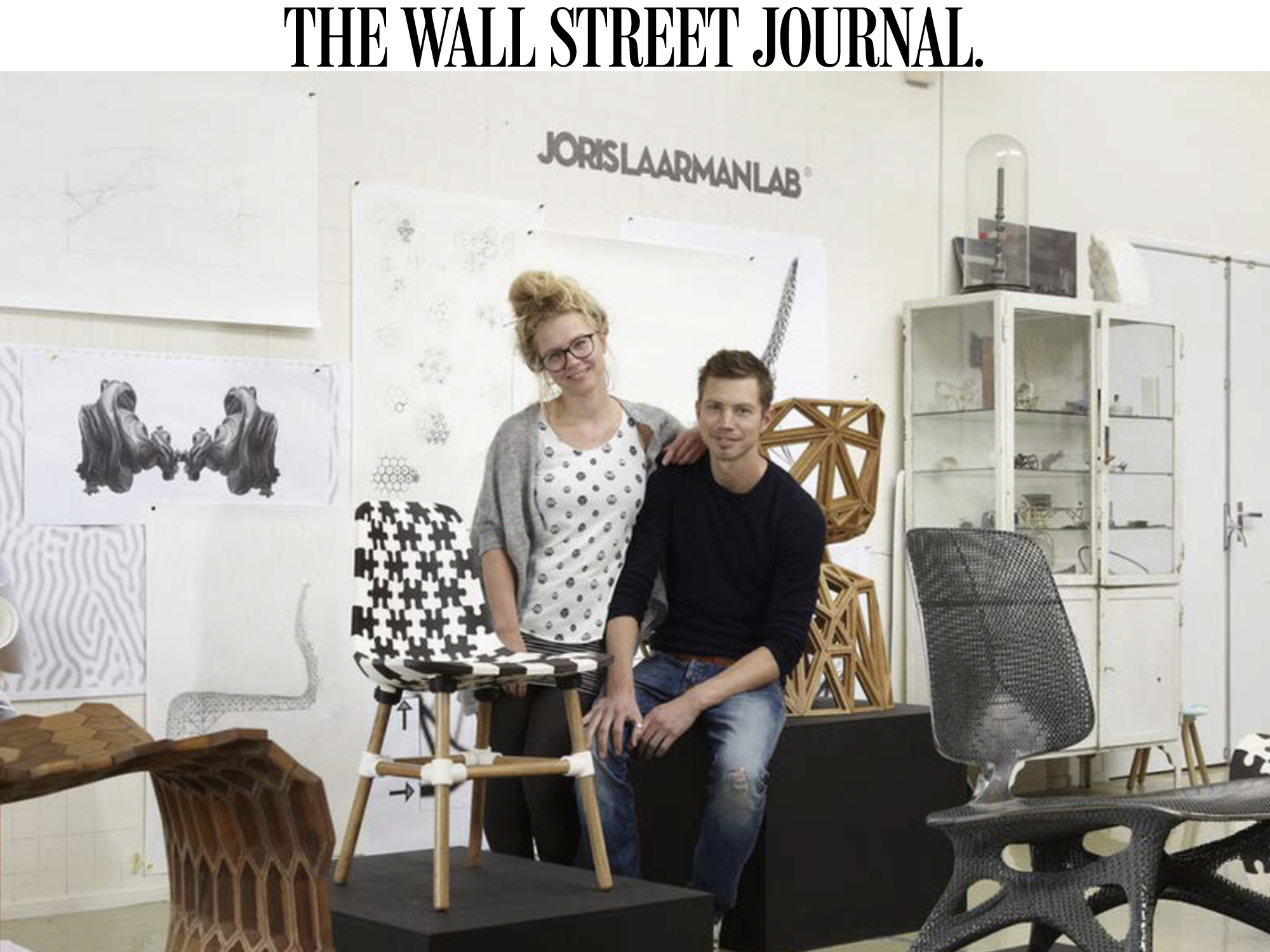

Joris Laarman, a Dutch designer, is pushing the frontiers of digital technology to create beautiful pieces of furniture.

At 35, he came of age at the time when the industrial era met the digital age.

“We are a sort of transition generation,” he explains. “With digital fabrication tools you can create much more complicated shapes. An algorithm or a robot is just like a chisel or a saw. It is a new tool for designers to work with.”

Mr. Laarman was born in the village of Borculo in the eastern Netherlands. His father was a police detective. His mother, after bringing up three children, trained as a nurse.

He studied at the Design Academy Eindhoven. His graduation show in 2003 featured a radiator made of concrete and aluminum fashioned into rococo swirls. It was a hit, and a slightly bewildered Mr. Laarman found himself thrust into a world of media coverage and contracts.

“I think it was just the right thing at the right time,” he says now. “But I was 23 and I had to set up a company, and I had no idea about how to deal with all the issues.” The success of Heatwave, now produced by Belgium-based Jaga, meant Mr. Laarman was in demand by major design companies. He set up a studio in Utrecht with the help of a government grant, and went on to collaborate with the designer lighting company Flos and Swiss furniture concern Vitra.

But he found collaborating with traditional design brands wasn’t his passion. “Working with companies usually means using techniques they already know,” he says.

In 2005, Mr. Laarman moved his studio to Rotterdam and began working on the series that made his name as an innovative designer. He was 25 and the Internet was taking off.

He began investigating the latest in digital technology and found a company that was using a computer algorithm to design car parts more efficiently. He felt the technique had huge potential, and was soon using the technique to create furniture. The first in the series was a side chair. He designed the seat and backrest; the computer then worked out the best way to support it. “I had no idea what it would end up looking like,” he says.

It looked fantastic, with a complex lattice of curving branches. Once the design was set, the chair was built using a 3-D printer to create a ceramic mold, then cast in aluminum. It is now in the collection of Amsterdam’s Rijksmuseum.

He named the collection Bone, because of the ability of bone to grow and repair itself. “If Mother Nature made a chair this is what it would look like,” he says.

The collection extended to armchairs, rocking chairs, a chaise longue, a bookshelf and a dining table. After a show at Design Miami in 2006, he was taken on by the New York gallery Friedman Benda.

Prices range from about $25,000 for a dining chair to about $500,000 to furnish an entire dining room.

As the Joris Laarman Lab started to grow, Mr. Laarman took on staff, including his partner, filmmaker Anita Star (they have two children, Charlie, 3, and Elphine, 15 months).

About five years ago the company moved to Amsterdam and now has 10 staffers and several freelance workers. Mr. Laarman continues to explore the boundaries of digital fabrication using 3-D printers.

A show in New York last spring featured his Dragon bench printed in stainless steel. The Vortex bookcase has flat shelves at the base that move into wild curlicues at the top.

Perhaps the most radical piece is called the Puzzle Chair (because it slots together like a jigsaw puzzle). The design can be downloaded, free, from www.bitsandparts.org and created in plastic by anyone with access to a 3-D printer. Mr. Laarman says about 10,000 people so far have done so.

Mr. Laarman’s company also is serving as an incubator for technology startups, he says, while he continues in design. He knows his love of high technology isn’t shared by everyone. “If a thing becomes too alien, you can’t relate to it,” he says. “I like to find the balance between craft and technology.”